DVP Vacuum Technology

DVP Vacuum Technology, a reality for nearly 50 years in the vacuum technology industry, competes globally in the production of Vacuum Pumps and Compressors found to be applied in many industrial areas. Constant customer care and listening are a true business mission and reach the highest levels in unique solutions: tailor – made products and processes, tailored to the needs of DVP Lab, DVP’s innovative and technological lab, surprising results through the use of software simulation of the latest generation, in the order to reduce the development time of new products.

The systems are designed and manufactured to be used in all the same individual pumps applications, and mainly in centralized vacuum systems, as units suitable for creating and maintaining a certain vacuum within the system that allows a proper operation of the equipment connected to it. The installation of a central production the equipment connected to it. The installation of a central production vacuum is advantageous especially in terms of energy savings, because the pumps automatically switch on only when needed by the user.

Application

Oil Lubricated Technology

Lubricated vacuum pumps are used when the intake flow may contain moisture, or when a better final pressure is required. These pumps may run continuously within certain pressure ranges, or connected to containers to be emptied, whose volume is appropriately sized for the pump flow rate. Long-term use at atmospheric pressure is not recommended. We recommend using the WR versions whenever the amount of intake vapour is considerable. The main application fields include: vacuum sealed packaging, thermoforming machines, glass or marble working machines, medical equipment, food-grade pastes or clay extruders.

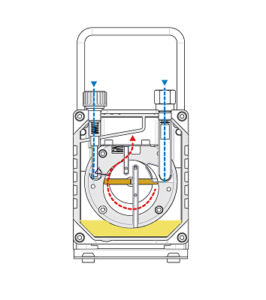

Oil Lubricated Rotary Vane Pumps

The main application fields of these pumps include : vacuum sealed packaging, thermoforming machine, glass or marble working machines, medical equipments, food grade pastes or clay extruders.

- Analytical field – ANF

- Centralized vacuum plant – CVP

- Construction – CST

- Environment – ENV

- Food and beverage – FAB

- Glass, stone and woods – GSW

- Packing food – PFD

- Packing non food – PNF

- Plastic, rubber and resin – PRR

- Pneumatic conveying systems – PCS

- Printing and paper – PAP

- Textile industry – TEX

Oil Seal Pumps

These kind of pumps can be made of a single rotor-stator group and are called Single Stage; or they can be made of two rotor-stator groups connected in series so the first group drain is connected to the second group intake system. The latter are called Double Stage.

The main application fields include: refrigeration and air conditioning systems, laboratory applications, freeze-drying, spectrometry and ultracentrifugation. Special Pneurop fittings are available to connect the various elements of the system.

- Centralized vacuum plant – IPC

- Ceramics – CER

- Chemical industry – CIN

- Electronics – ELT

- Metallurgy, metalization and semiconductors – MMS

- Plastic, rubber and resina – PRR

- Refrigeration and conditioning – RAC

Dry Vacuum Technology

Dry Vacuum Pumps can run continuously exclusively with clean, dry air. Unlike other kinds of pumps, the dry rotary vane pumps can run at any pressure. Maintenance is very easy and consists of replacing the vanes and cleaning the filters.

The main application fields include: suction cup movements, automatic machines, woodworking machines. Dry vane vacuum compressors have no particular restrictions on their use, except for the maximum operating pressure which should not exceed the rated value. For this reason it is always recommended to use a safety valve.

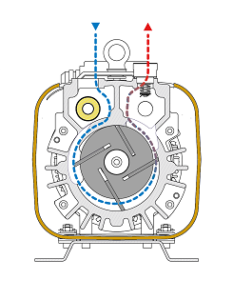

Oil-Free Rotary Vane Pumps

The main application fields include: suction cup movements, automatic machines for packaging, woodworking machines, wood presses, plastic material presses, banknote counting machines. In construction they are used in sprinkler for plaster, low pressure printing machineries, pneumatic conveyor systems.

- Analytical field – ANF

- Centralized vacuum plant – CVP

- Construction – CST

- Environment – ENV

- Food and beverage – FAB

- Glass, stone and woods – GSW

- Packing food – PFD

- Packing non food – PNF

- Plastic, rubber and resin – PRR

- Pneumatic conveying systems – PCS

- Printing and paper – PAP

- Textile industry – TEX

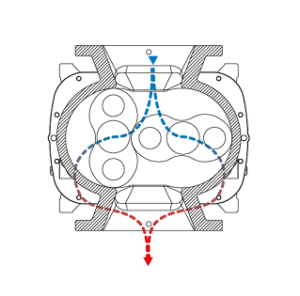

Claw Pumps

The main application fields include: refrigeration and air conditioning systems, laboratory app, freeze-drying, spectrometry & ultracentrifugation. Special Pneurop fittings are available to connect the various elements of the system.

- Centralized vacuum plant – IPC

- Ceramics – CER

- Chemical industry – CIN

- Electronics – ELT

- Metallurgy, metalization and semiconductors – MMS

- Plastic, rubber and resina – PRR

- Refrigeration and conditioning – RAC

Piston Pumps

Piston pumps may be used in presence of moisture and have no particular restrictions on use. Versions (series ZA box) are also available with safety guard and intake filter for use as mobile units. The main application fields include: electromedical, suction cups conveyors, laboratory applications and construction.

- Analytical field – ANF

- Chemical industry – CIN

- Construction – CST

- Electronics – ELT

- Environment – ENV

- Medical industry – MED

- Plastic, rubber and resin – PRR

- Printing and paper – PAP

Lobe Pumps

The system is integrated within the inverter, and it continuously sends data in order to manage the electric motor speed variation. This procedure allows the system to fully use the volumetric capacity of BCA pump. Moreover, the AdaptShield system protects the BCA pump from possible malfunctions. Typical app in pharmaceutical sector, in vacuum metal treatment, in electrial transformer oil outgassing, in food packaging

- Chemical industry – CIN

- Electronics – ELT

- Metallurgy, metalization and semiconductors – MMS

- Packing food – PFD

- Packing non food – PNF

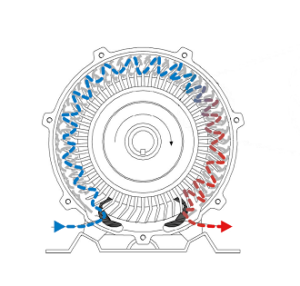

Blowers

The operating principle of the blowers is pretty simple: a small wings equipped rotor rotates inside a stator.

Small vortexes of air created by the centrifugal force and the rotation are dragged by the vanes from the aspiration toward the drain. There are no parts in contact, thus the blowers do not require routine maintenance but, since the intake air is also used as cooling fluid, they can operate continuously only within certain ranges of pressure.

To prevent a damage of the engine it is indeed necessary to install vacuum and pressure limiting valves. This product is very versatile and is not particularly delicate. If used as a compressor, the output flow is clean and free of pulsations.

The main application fields include: pneumatic conveying, suction cups conveyors, purification or water oxygenation.

- Chemical industry – CIN

- Electronics – ELT

- Environment – ENV

- Food and beverage – FAB

- Glass, stone and woods – GSW

- Industrial parts cleaning – IPC

- Medical industry – MED

- Metallurgy, metalization and semiconductors – MMS

- Packing food – PFD

- Packing non food – PNF

- Plastic, rubber and resin – PRR

- Pneumatic conveying systems – PCS

- Printing and paper – PAP

- Textile industry – TEX

Contact Us

We are here

Plaza Pasifik B4/86 - Jl. Boulevard Barat Kelapa Gading - Jakarta 14240

Phone : +62 21 451 3089

Fax : +62 21 451 5743

Email : jotam@cbn.net.id