Corona Treatment and Plasma Treatment Systems

for Improved Surface Adhesion

3DT is a leader in the surface treatment industry because only 3DT :

- Supplies comprehensive surface treatment solutions including single source design, manufacture, installation, and service

- Provides truly custom-engineered systems

- Offers a complete line of surface treatment equipment for nearly all 3-dimensional and 2-dimensional (film/web) applications

- Custom systems may include product handling and automation

- Our systems are built in Germantown, Wisconsin, USA with proven technology, robust design and state-of-the-art components

- Backs up each sale with a knowledgeable, experienced sales and service team dedicated to excellent customer service and your success

3DT’s Three–Dimensional Surface Treatment Product Line

PolyDyne

Features :

- Universal Input allows operation between 100-240 VAC, 50/60 Hz

- Sophisticated remote interface that can be used to enable the generator, set and monitor output power level

- Color touchscreen where the user can monitor all system parameters, view the data log, alarm history and receive troubleshooting help

- Programmable for various treatment modes- product sensing, timed, or continuous

- Data log to record operation history to ensure maximum efficiency

- Compact design allows for easy integration into production lines

Multidyne

MultiDyne’s corona discharge is created with the use of the “short circuit” principle generated between two electrodes at a high voltage potential. An air stream passes between the electrodes spreading the corona field uniformly onto the surface receiving treatment and thereby improving surface energy and adhesion. Corona treatment (sometimes called blown arc plasma) is highly useful for a wide variety of applications. Such as, treatment on surfaces adjacent to metal inserts or areas held in a metal fixture, as well as flat or complex, hard to reach 3D parts. These types of surface treatment challenges are easily overcome with the MultiDyne system.

FlexiDyne

Now you can expand your competitive edge. FlexiDyne Pro, now thoroughly updated, is a self-contained floor model corona treating system that is capable of treating many 3-dimensional plastic parts. Any non-metallic items that will fit through FlexiDyne Pro’s 12″ wide by 1.5″ high opening can receive uniform corona treatment of all exposed areas. FlexiDyne Pro is highly successful in improving the surface energy on polyethylene and polypropylene parts.. 3DT’s FlexiDyne Pro corona treating system is: flexible, cost-effective, operator friendly

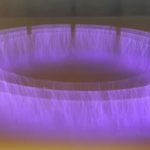

BottleDyne

Utilizing corona treatment, 3DT’s self-container BottleDyne™ system sets new standards for surface treatment technology. It is now possible to corona-treat PE, PET and PP cylindrical containers in fast-paced molding, printing, filling or labeling production lines. Bottles quickly rotate through the system receiving 360° of treatment on all exposed surfaces.

BottleDyne’s corona treatment is highly effective in improving adhesion, yet performs without adverse effects to the surface of containers. This self-contained floor model is built with state-of-the-art components and designed for easy installation into production lines or employed as a stand-alone workstation.

TubeDyne

TubeDyne is a compact, self-contained tabletop corona treating system including integrated generator, transformer, electrode assembly, holding fixture and ozone filter. The system is PLC-controlled and features an operator console with a human machine inter face (HMI), including: monochrome touch screen with status menu, run time log, service hour log and alarm/trouble-shooting screen. The TubeDyne advantages:

- Self-contained compact tabletop system

- Enhances bonding of housing to medical tube ends

- Powerful repeatable and uniform treatment

- Treats up to 0.375″ in diameter without set-up changes

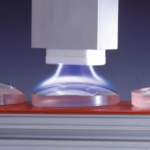

PlasmaDyne

Here are the specifics on PlasmaDyne Pro’s new features and benefits:

- Adjustable power level up to 600W to achieve desired treatment levels- turn up the power to raise surface energy on resistant substrates or lower the power for delicate substrates.

- Color touch display for monitoring all system parameters, including troubleshooting and fault log.

- Modular power supply for treating heads allows for quick, easy changes to keep production running.

- Active power correction for highest efficiency and lowest operating cost.

- Compact and economical:

Applications

We are here

Plaza Pasifik B4/86 - Jl. Boulevard Barat Kelapa Gading - Jakarta 14240

Phone : +62 21 451 3089

Fax : +62 21 451 5743

Email : jotam@cbn.net.id